Engineering Rubber Since 1972

The air/nitrogen charge is contained within the bladder inside the tank. The charge does not come into contact with the liquid in the tank and so cannot be absorbed. Air charge losses due to absorption are therefore minimal.

The pumped media from the mainline, flows in and out of the vessel and it will come in contact with the bladder, so compatible materials must be selected.

The bladder is often made from a High Tensile Rubbers with or without reinforcements, in Neoprene, Nitrile(Buna-N), Food Grade Butyl or Hypalon Rubbers, and may be expanded to fit the entire vessel. The Bladders are fitted with a Flange at the top as per Client’s vessel details.

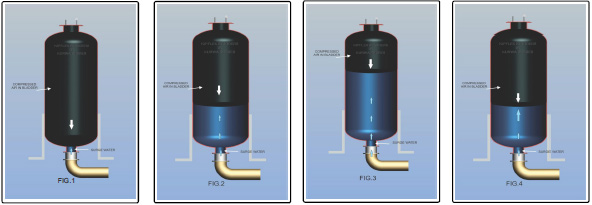

The bladder will typically be pre-charged with Air/Nitrogen after installation (Fig.1) with a pre-determined pressure as per surge/hydraulic analysis, to give the correct operating level in the tank when the unit is connected to the mainline at the working pressure.

When the mainline valve is opened, the water/media will enter the vessel under static condition and begins to compress the Gas filled bladder (Fig.2). The static line pressure will be higher than the pre-charge pressure. The water/media entering the vessel will further compress the pre-charged Bladder until a perfect balance is created between the water and the compressed bladder.

On Pump Tripping or shutting the surge created in the mainline will push the water into the vessel. This pressure will be absorbed by the compressing bladder and effectively reflex pressure will be applied on the surge. After multiple hammerings & oscillations, it will even out the pressure (Fig3,4) of the mainline and create a static state, without damaging the pipeline. Eventually the entire system will return back to dynamic state( Fig.2) for the next surge.

Capacities available are from 100 liters to 100,000 liters.